M. Mor[1], C. Seneci[1], V. Zacché[1], C. Remino[1], G. Petrogalli[1], D. Fausti[1],

[1]Polibrixia, Brescia, Italy

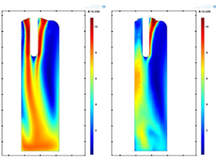

This paper presents the study and design of a new generation oven for PET blow-molding machines. The design faced several technical challenges such as: the temperature distribution in the critical areas, the sharp curvature radius, the high PET thermal inertia and the presence of boundary elements, which affected the overall performances. The work included an analysis of the preform material and geometric influence on the heating and transformation process, followed by the definition of the model to implement in a simulation. Finally a series of simulations aimed to simulate the infra red heating system and the convective cooling system, necessary to control the heating process, achieving the ideal temperature distribution, more efficiency, energy saving and higher modularity.